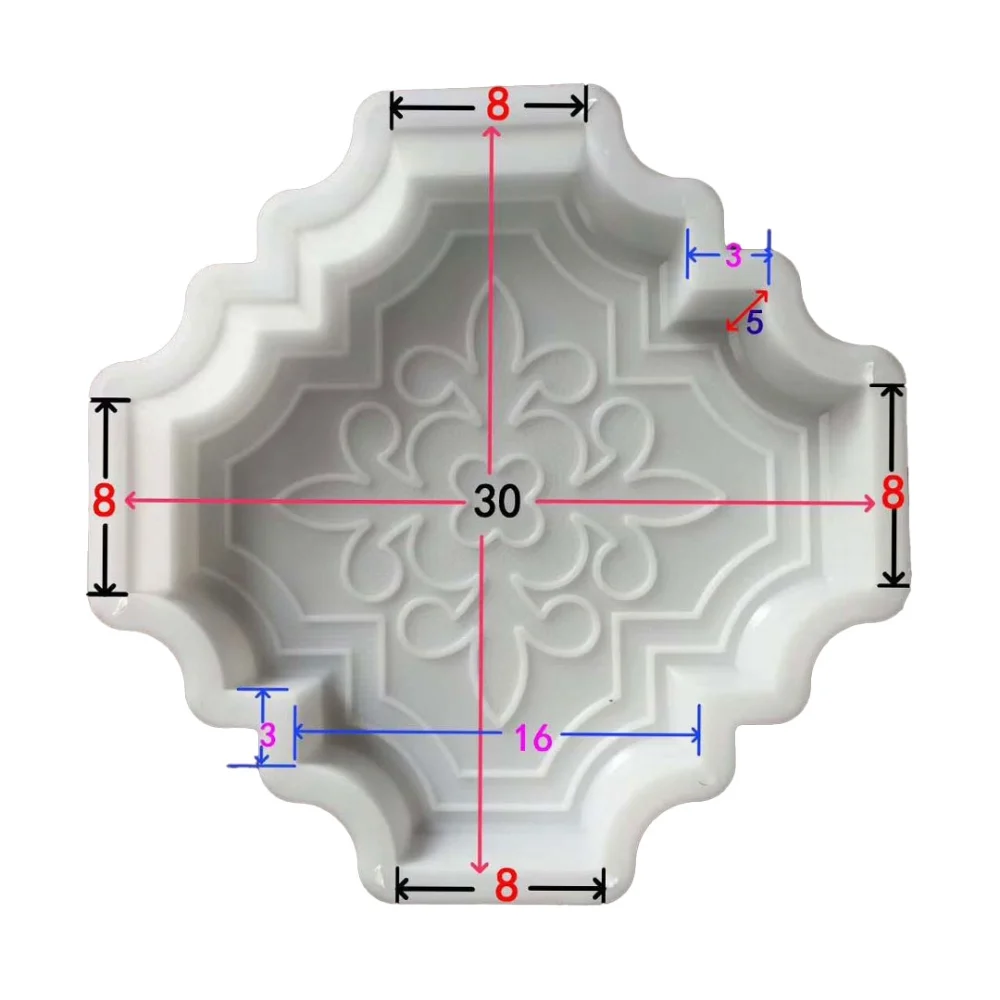

Pavement Access Road Molds

High-Quality Plastic Moulds to Shape Your Ideal Concrete Pavers

Plastic concrete paver moulds are used to create concrete pavers. They're durable, versatile, and ideal for various paving projects like garden paths and driveways.

Inquiry Now

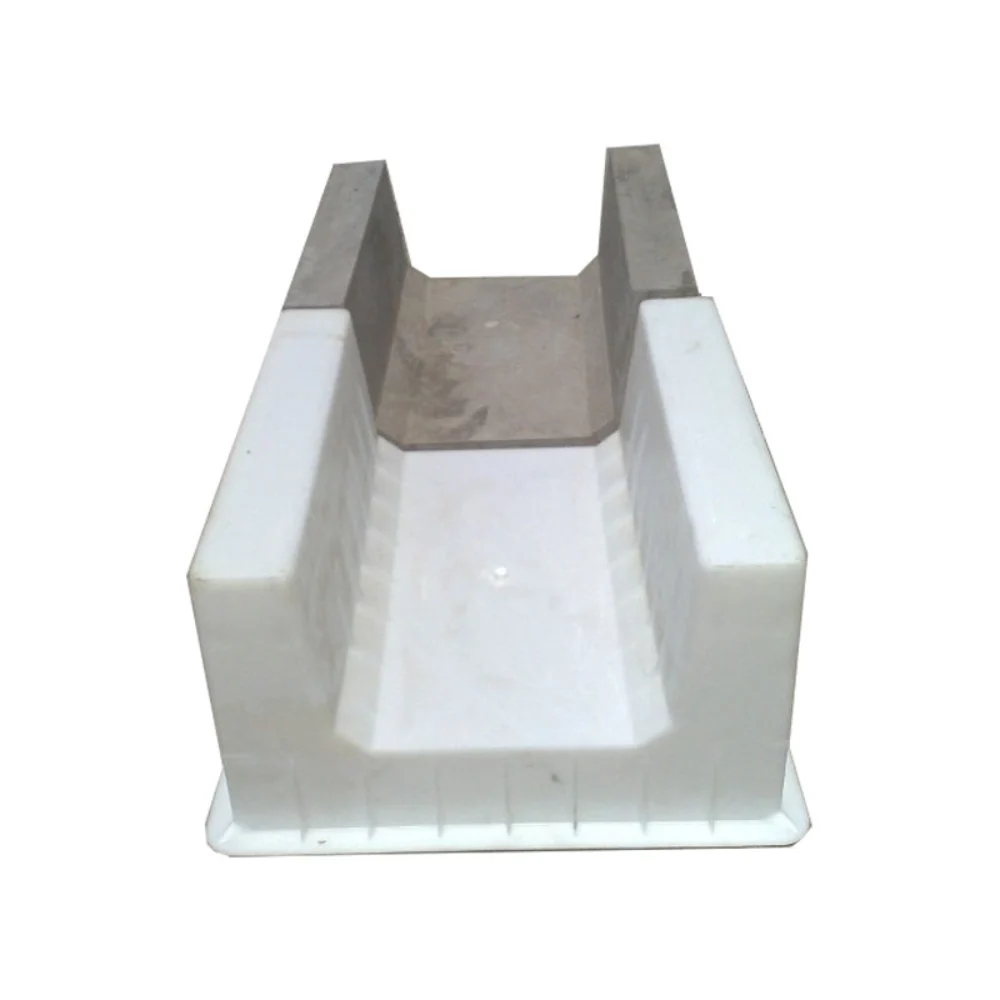

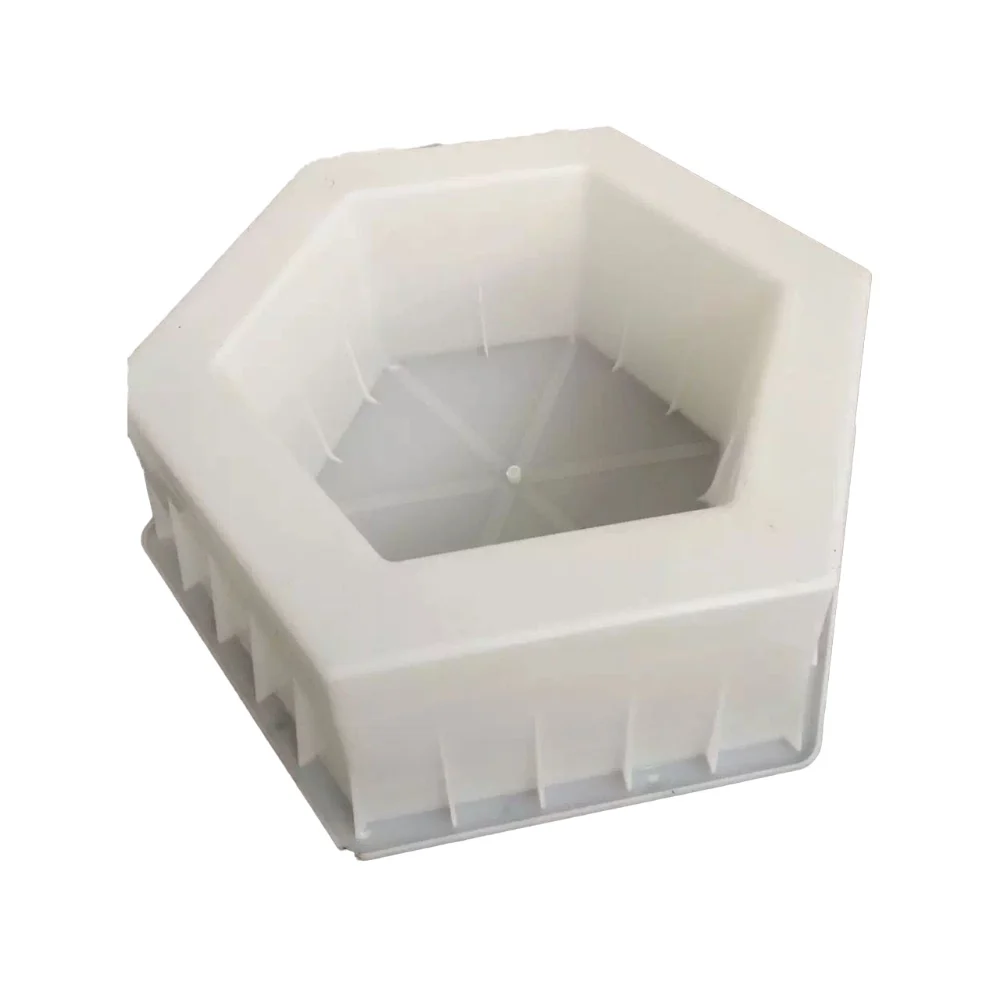

What is the plastic mould for Concrete Paver?

A plastic mould for concrete paver is a tool used in the manufacturing process of concrete pavers. It is typically made from plastic materials and is designed to give shape and texture to the concrete pavers. The moulds come in various shapes and sizes to create different patterns and designs for the pavers. They are used to cast the concrete mixture into the desired shape and then removed once the concrete has set. Plastic moulds for concrete pavers offer several advantages, including ease of use, durability, and the ability to create complex designs. They are also relatively lightweight and easy to handle, making them a popular choice for both professional and DIY applications.

Features of the Injection plastic moulds

| Place of Origin | Shanghai , China |

| Brand Name | OCEANA |

| Model Number | |

| Product Name | Concrete Paver |

| Size | |

| Precision | 0.005mm |

| Mould Life | 2-3 Years |

| Lead time | 3-10 days after complete your payment |

| Quality | High Level |

| Advantage | Durable and easy demoulding |

| Packaging Details | woven bag |

| Selling Units | Single item |

| Single package size | 100X30X30 cm |

| Single gross weight | 1-3.000 kg |

| Service | OEM ODM |

- Lowest cost, light and easy to release, less labor, economical;

- Smooth surface, clear text patterns;

- Beautiful and practical, no internal defect, simple operation;

- Equipped with moulds and vibration table;

- Has good toughness for using unique technology.

Why choose us?

Superior Materials: We use imported PP, ABS material, environment protection and non-poison.

PP material:

- High crystallinity, regular structure, which has excellent mechanical properties.

- PP having a good heat resistance, the article can be sterilized at a temperature above 100 ℃, without being subject to external conditions, 150℃ not deformed.

ABS material:

- ABS with excellent mechanical properties, and its excellent impact strength, can be used under low temperature; ABS good wear resistance and good dimensional stability, but also has oil resistance, can be used for medium load and low speed of the bearing.

- ABS electrical insulation is better, and almost independent of temperature, humidity and frequency, can be used in most environments.

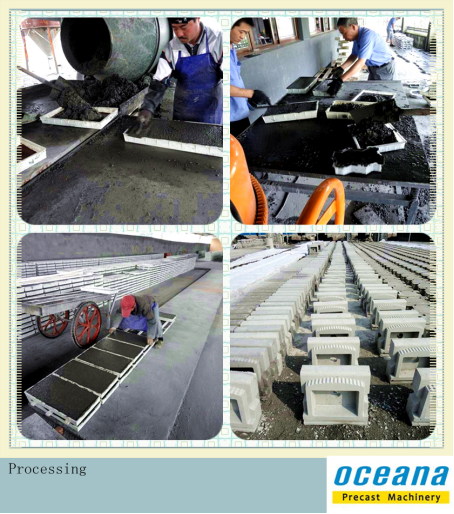

Product Processing:

Injection molding process mainly consists of mold closing - filling - pressure - retention - cooling - stripping

If you are interested in any of our products, please contact us, We will send you the catalog.

Other Products

Leave Your Message

If you have any questions, please leave a message, we will reply as soon as possible.

Send Message